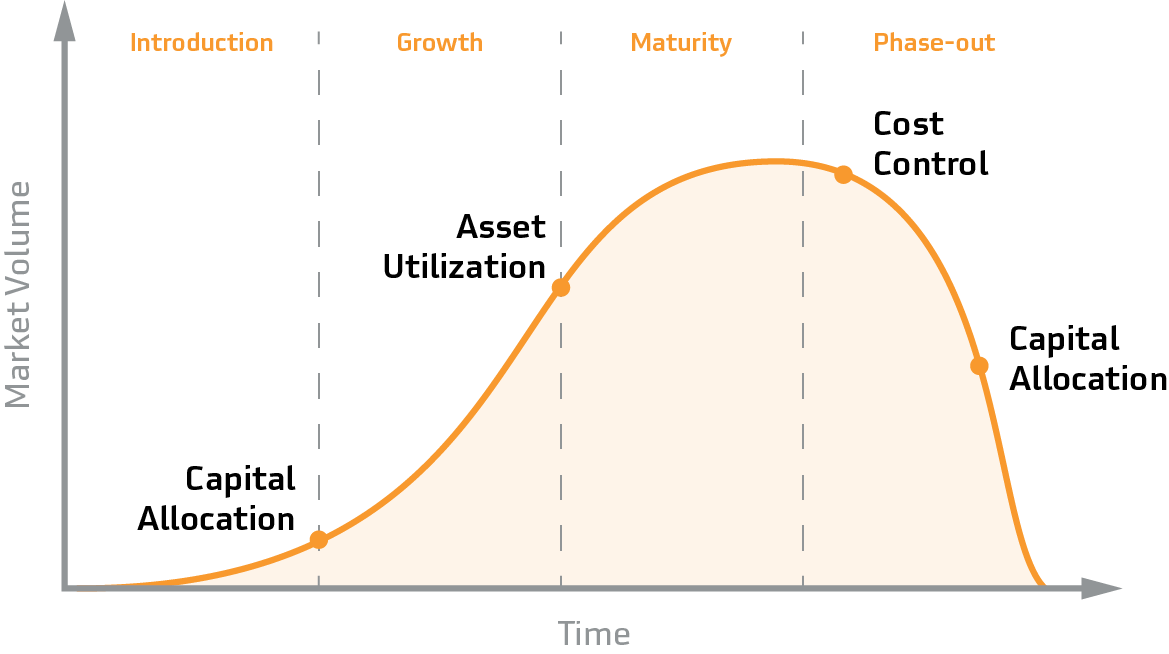

With Asset Portfolio Management, the lifespan of the installation park is monitored and we initiate investment projects to maintain and strengthen the competitiveness. It is important to know which installations you are managing, what the condition is and how long these installations last.

With optimising the Life Cycle Plans, we take this to the next level. In addition to determining the ideal moment to renew assets, we also look at how we can optimise all operational, maintenance and engineering actions. Value creation does not happen overnight: we have to optimise every aspect end-to-end. A combined approach of Operational Excellence, Maintenance Excellence and Engineering Excellence.

The Life Cycle Plans are optimised per asset family. We use the following step-by-step plan within a pre-agreed time frame:

- Collect data and gain insights;

- Analyse bottlenecks;

- Build and refine models;

- Adjust policy.

Life Cycle Plans provide operational, tactical and strategic benefits

Due to the cyclical nature, we embed the continuous improvement culture in all steps. Pain points are substantiated with facts and figures. Points for improvement are worked out in multidisciplinary teams.

Due to the cyclical nature, we embed the continuous improvement culture in all steps. Pain points are substantiated with facts and figures. Points for improvement are worked out in multidisciplinary teams.- By using the available data, efforts are also made to improve the quality of the data. New inspection plans and improved data capture (collecting and centrally storing data) eliminate the blind spots.

- The structural integration of operational, maintenance and engineering insights about a certain asset family, ensures that we stop the silo thinking and start optimising the entire chain. This results in better management of the installations, better insights of the condition, but also in life time extension and a substantiated long-term replacement plan.

Want to improve your Maintenance & Asset Management organisation?

Contact us and let’s get started.

Social