Congreso de Mantenimiento

05 September 2018 t/m 06 September 2018 - Presenters: Various During this event Guy Delahay will give a VDMXL presentation.

During this event Guy Delahay will give a VDMXL presentation.

30 years of experience in Improving Maintenance, Reliability and Asset Management. Helping organizations to achieve better SHEQ compliance, higher uptime, lower costs and more balanced CAPEX investments. Industry knowledge of Food & Beverage, Life Science, Chemical, Automotive, Paper, Energy and Utility market. During my career I have helped companies like Mars, PepsiCo, Bavaria, Givaudan, GlaxoSmithKline, Sanofi, Ipsen, Johnson & Johnson, DSM, BASF, Huntsman, Volvo Cars, NedCar, DAF, Smurfit Kappa, Stora Enso, Jacob Holm Group, Farm Frites, Aviko, TAQA Energy, Essent Energy, Elia, ELES, Port of Rotterdam and several public water companies.

Guy was chairman of the Dutch Maintenance Association, is a regular speaker and chairman on international maintenance management conferences. Co-author of the book “Value Driven Maintenance & Asset Management, Competing with Aging Assets” and co-founder of Mainnovation. Thorough experience in (Maintenance & Asset Management) Strategy & Maturity Assessments, Benchmarking, KPI Performance Management, Implementing Best Practices, Selecting and Implementing CMMS/EAM systems like SAP, Maximo, Infor and Ultimo.

Summary of the presentation:

Value Driven Maintenance & Asset Management: Competing with Aging Assets

Manufacturing industry is aging. Recent research shows that almost half of our industrial equipment needs replacement between 2015 and 2025. Because of the economic crisis, many companies lacked the financial resources to do so. As plant closure becomes a real threat, lengthening the service life of assets is often the only way to keep industrial production. And this needs to happen in a strongly globalizing economy that is facing increasing competition from low-wage countries that are home to relatively new and modern plants.

This is the new challenge facing the modern-day maintenance manager. Our equipments must become more competitive, this requires more than just maintenance. The technical departments of the future must be drivers of improvement. They must extend the lifetime of assets, replace parts that need to be replaced, and modernize the systems that are in place. And they must do this so as to create maximum economic value for the business.

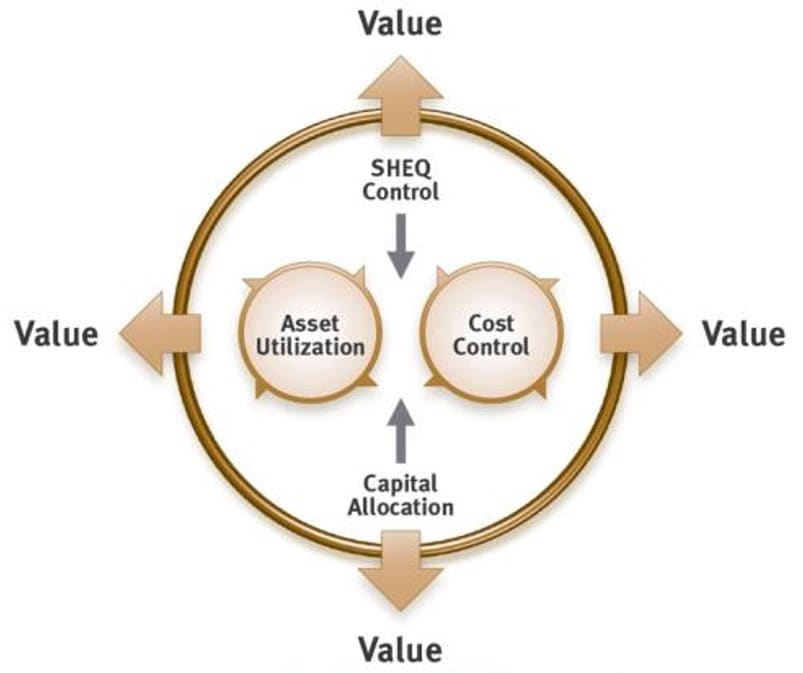

Following the big success of our first book, Mainnovation has developed a new methodology: Value Driven Maintenance & Asset Management, or VDMXL. VDMXL explains how to create maximum economic value with an existing plant, fleet or infrastructure using a professional management approach. Key features of the methodology include:

• KPI performance measurement at all levels of the organization

• Use of best practice work processes

• Long-term monitoring of the asset portfolio

• Continuous improvement of preventive maintenance plans and work processes

• Professional use of modern EAM solutions

• Effective Change Management and involvement of Top Management

• Complete coverage of the ISO 55000 standard

Social